High Polymer Sound Insulation Felt

High performance and high-quality polymer-metal sound insulation felt with excellent transmission loss. It is made of environmental protection materials and renewable polymer containing no halogen, thereby being green and environmental-friendly; it does not contain formaldehyde, benzene, asbestos, radioactive substances and other constituents harmful to the human body and does not contain substances depleting ozone, thereby fully meeting the international volatile organic compound emission standards.

Description:

High Polymer sound insulation felt has no material resonant frequency. The thin and high-quality material is stuck to the mechanical equipment shell and the engine room guard and can provide obvious noise control and vibration absorption data. The development of OFF metal damping and sound insulation felt meets the active sound insulation for the power cabins of industrial equipment and traffic equipment and the passive sound insulation acquirements for the carriage air noise and vibration.

It can effectively absorb and obstruct the noise transmitted through the wall, the ceiling and the floor structure by fulling utilizing the mass law and damping principle of the architectural acoustic material. With the strong damping property and surface density, the sound reduction index of the raw material is greatly improved. OFF metal damping and sound insulation felt is compounded on the surfaces of the gypsum board, the wooden board, etc. (Zolpidem) to improve the sound reduction index of the raw material by 10-29 dB.

Model:

F10 / F20 / F30

Dimension:

F10 – 12000mm (L) x 610mm (W) x 1.0mm (T)

F20 – 6000mm (L) x 610mm (W) x 2.0mm (T)

F30 – 4000mm (L) x 610mm (W) x 3.0mm (T)

Weight:

F10 – 2.4kg/m² (18kg/roll)

F20 – 4.8kg/m² (18kg/roll)

F30 – 7.2kg/m² (18kg/roll)

Features:

High Polymer sound insulation felt has good fire resistance, heat resistance, elasticity, flexibility and tensile strength. It can be cut with the wallpaper cutter, the scissors and other tools, or be fixed with the code nails or adhesive for building sound insulation, and the OFF Metal damping and sound insulation felt for the mechanical equipment can be matched with the sheet metal through the staple bolt or adhesive. OFF metal damping and sound insulation felt is the integrated material which is easy to construct and is not limited by shape, structure and space.

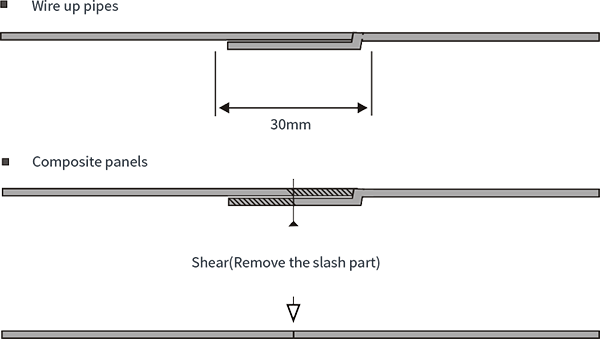

Installation method:

Gap installation method:

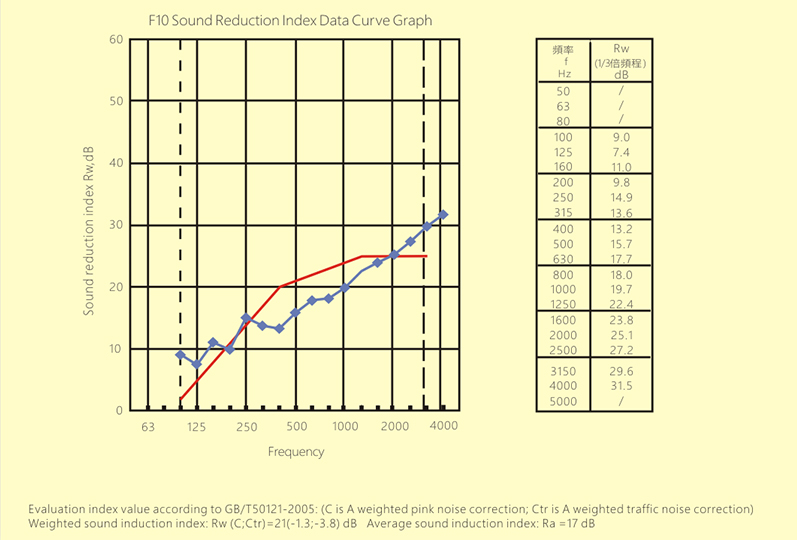

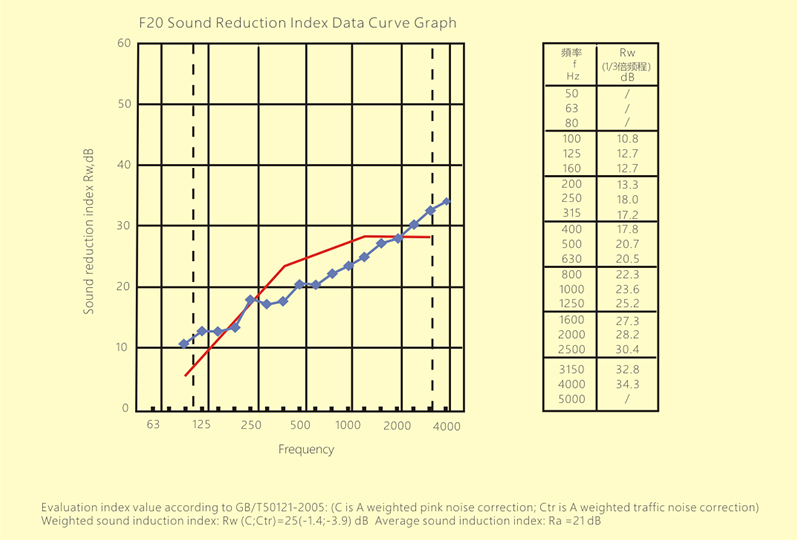

Sound Reduction Index

F10

F20

Comparison with Similar Products

Ordinary Sound Insulation Felt

High Polymer Sound Insulation Felt

F10 / F20 / F30

Material:

The wasted rubber is used as the raw material for production, the material has extremely low environmental protection and strength, and the smell of chemical agglutinant is emitted seriously to pollute the indoor air. The surface density and the sound insulation index of the material are low so that the sound insulation effect is difficult to meet the standards.

The fully new environmental-friendly and silicone materials are adopted, the chemical agglutinants harmful to the health are not contained, and sound insulation felt is physically pressed and molded. With the surface density up to 2.4Kg, the activity with the frequency of 125-20KHz is effectively obstructed, and the low-frequency wave sound reduction index is immediately promoted by matching with the rear cavity structure.

Installation method:

With the impact of material and production process, the phenomena such as fractures and cracks are easy to occur.

The material can be folded, bended and cut arbitrarily and can be installed and fixed by gluing and nailing and other ways.

Sound insulation performance:

Poor. The sound insulation property is improved by increasing the material thickness or matching with other materials.

Excellent. The proportion of high polymer is over 90%; the surface density is maximum in the similar products; the sheet thickness is only 1.0 mm, but the sound reduction index is up to 20dB; the sheet thickness is only 2.0 mm, but the sound reduction index is up to 25dB.

Fireproof performance:

Not having flame retardant properties.

Flame retardant. It is not impacted by the service environment, is moist-proof and thermally insulated and can be applied in all fields.

Environmental protection:

It may cause toxic pollution to the human body and the environment.

Safe and nontoxic.

Sound Insulation Indicator:

Low

High