Step 1

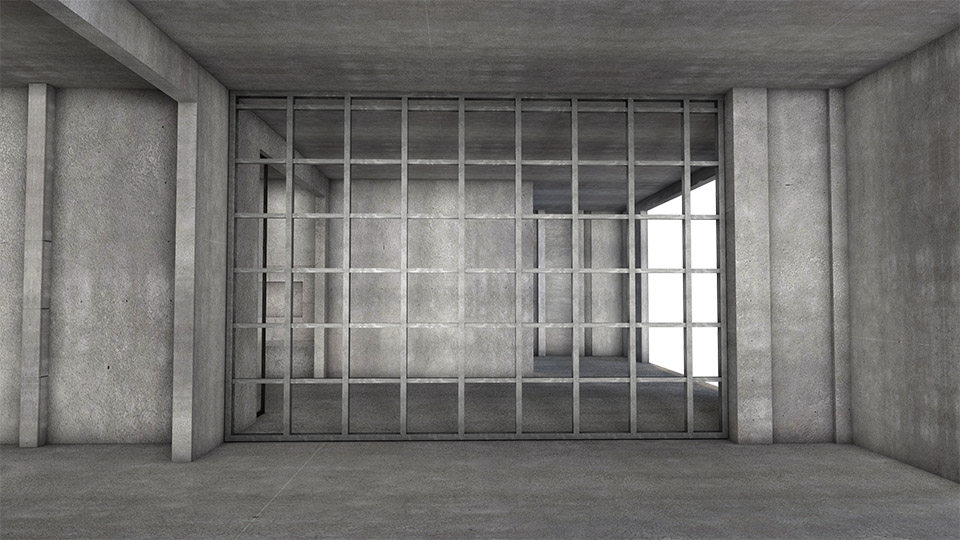

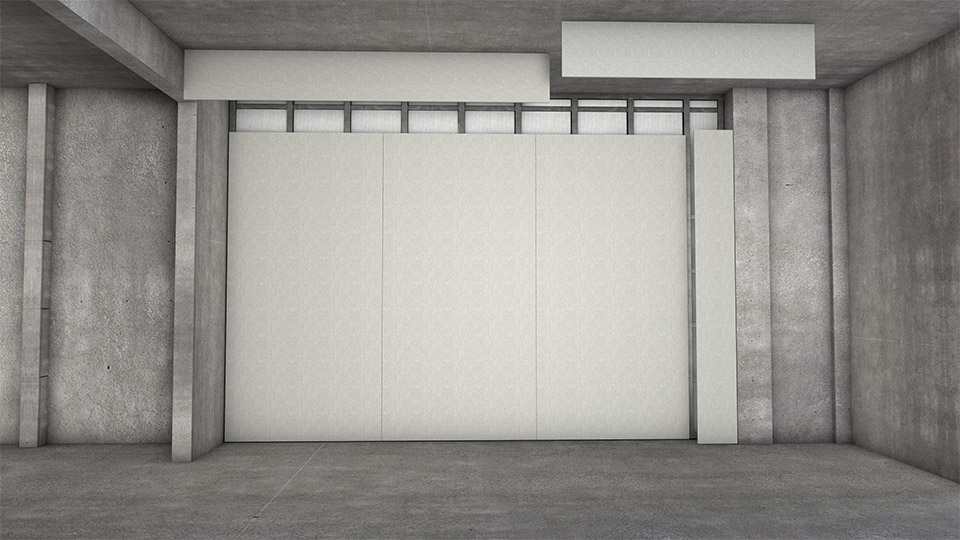

Hollow bricks and partition wall both cannot meet sound insulation requirements for the hotel. To keep the original wall structure, adding a sound insulation layer is the best way to reduce noise.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

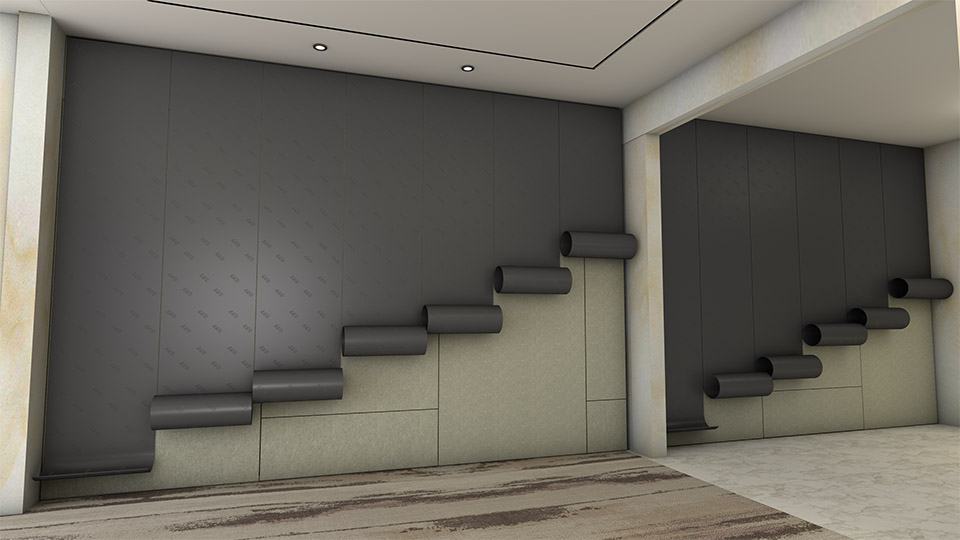

Weight of sound insulation structure: ≤50kg/m². The thickness of sound insulation structure: ≤75mm.

The distance of keel structure ≤400mm, cavity filled with acoustic fiber. Suggested material for insulation structure.

The least thickness in structure to achieve the required sound insulation effect.

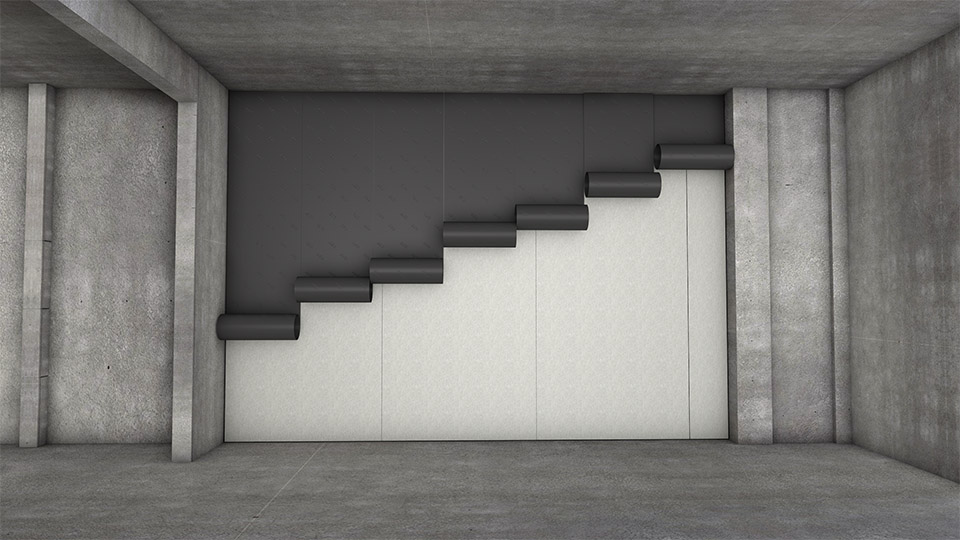

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Weight of sound insulation structure: ≤100kg/m². The thickness of sound insulation structure: ≤120mm.

The distance of keel structure ≤400mm, cavity filled with acoustic fiber. Suggested material for insulation structure.

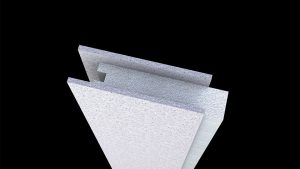

Product name:

White acoustic wool

Model:

ME48-50

Specification:

H1200 x W600 x D50mm

Weight:

48kg/m³

The sound absorbing wool is currently recognized as the most superior material in this application, and it is widely used for thermal insulation, sound absorption, and noise reduction. It has the advantages of being fireproof and moisture-proof, non-toxic, durable and chemically stable, low unit weight and low heat conductivity.

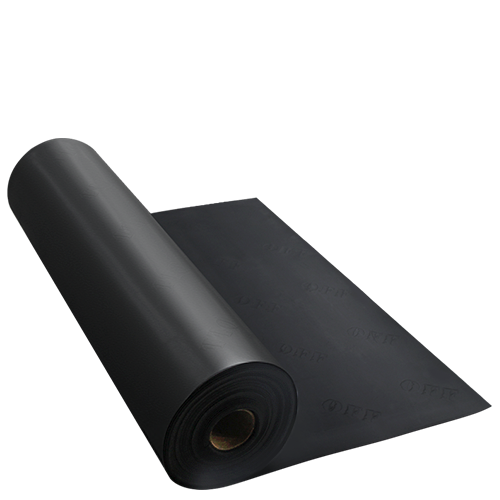

Product name:

High polymer sound insulation felt

Model:

F10 / F20 / F30

Specification:

F10 – W610 x L12000 x D1.0mm

F20 – W610 x L6000 x D2.0mm

F30 – W610 x L4000 x D3.0mm

Weight:

18kg/roll

High Polymer sound insulation felt is a high performance and high-quality polymer sound insulation felt with excellent transmission loss. It is made of environmental protection materials and renewable polymer containing no halogen, It does not contain formaldehyde, benzene, asbestos, radioactive substances and other constituents harmful to the human body and does not contain substances depleting ozone, thereby fully meeting the international volatile organic compound emission standards.

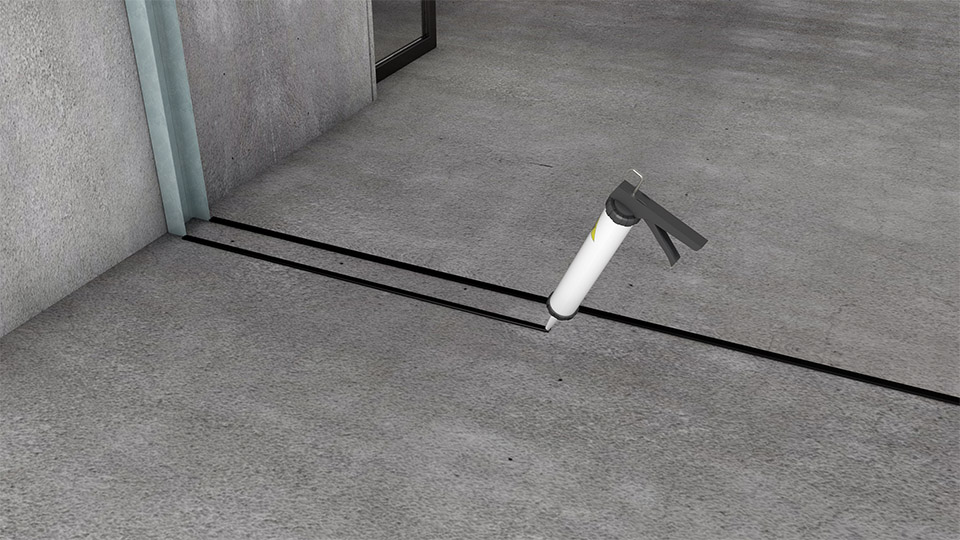

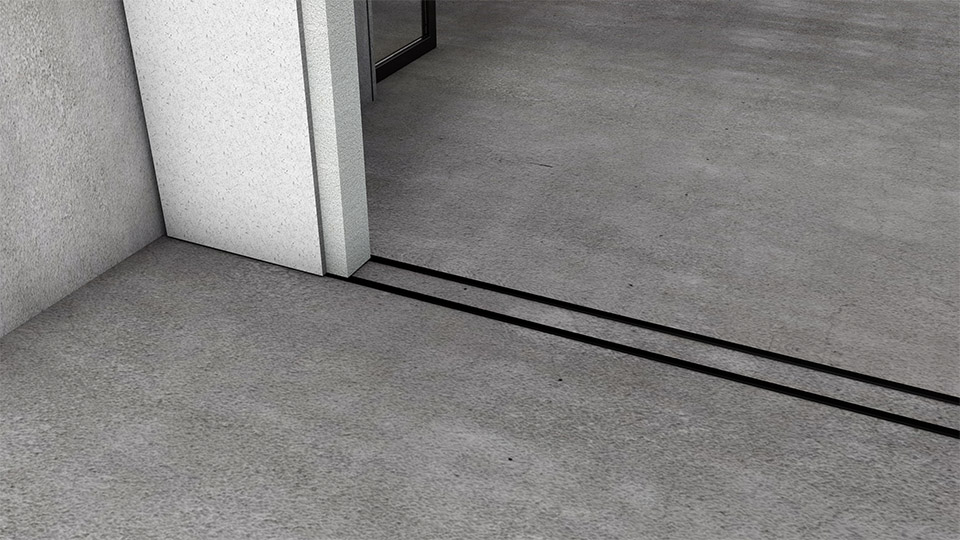

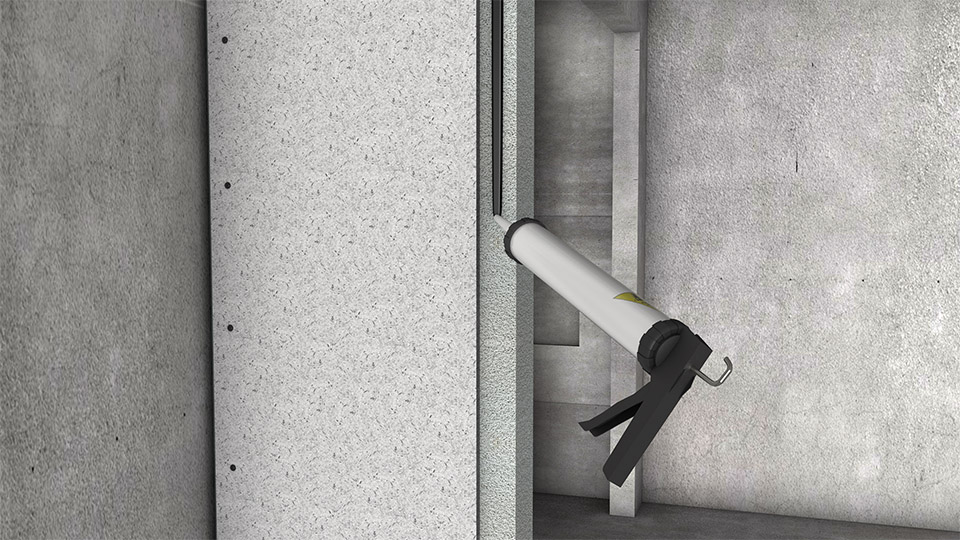

Product name:

Acoustic damping sealing glue

Model:

G600

Specification:

300 x Φ50mm

Weight:

600ml

The formula characteristics are effectively used for sealing the joints of the inorganic material boards and fixing the material, rubber and other materials with the vibration damping adhesive. There is no corrosion to the organic and inorganic materials, metal and rubber. The aging resistance is excellent, the adhesive property is good for multiple base materials, the moisture resistance and the high-low temperature adaptability are strong (use in the temperature range of -20°C to 100°C), and the performance is steady and reliable.

“OFF” Lightweight Sound Insulation block enhances the sound insulation effect at affordable cost, with superior soundproof performance.

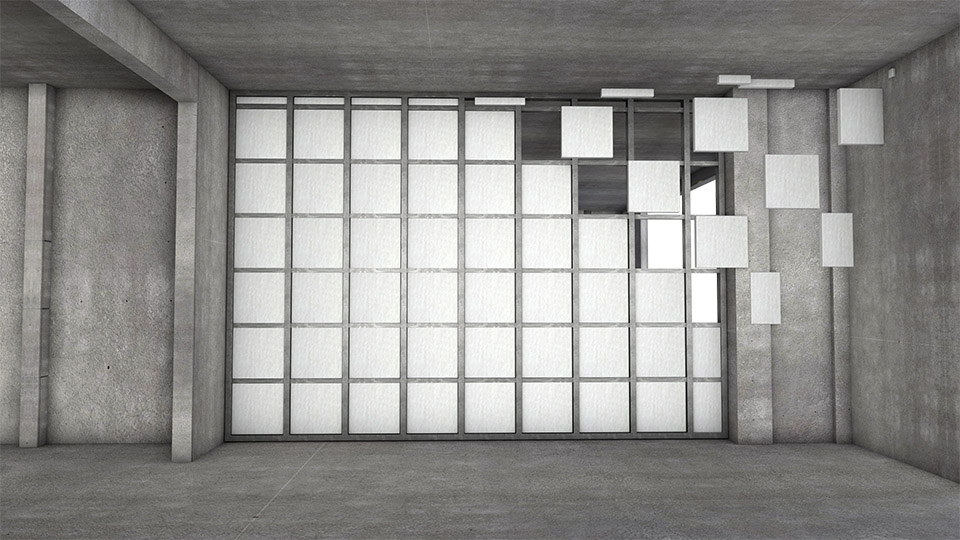

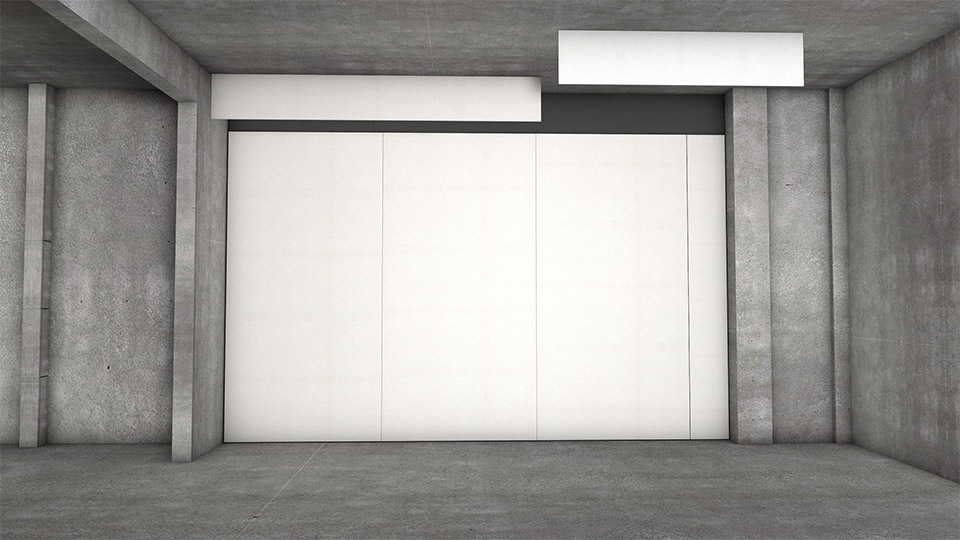

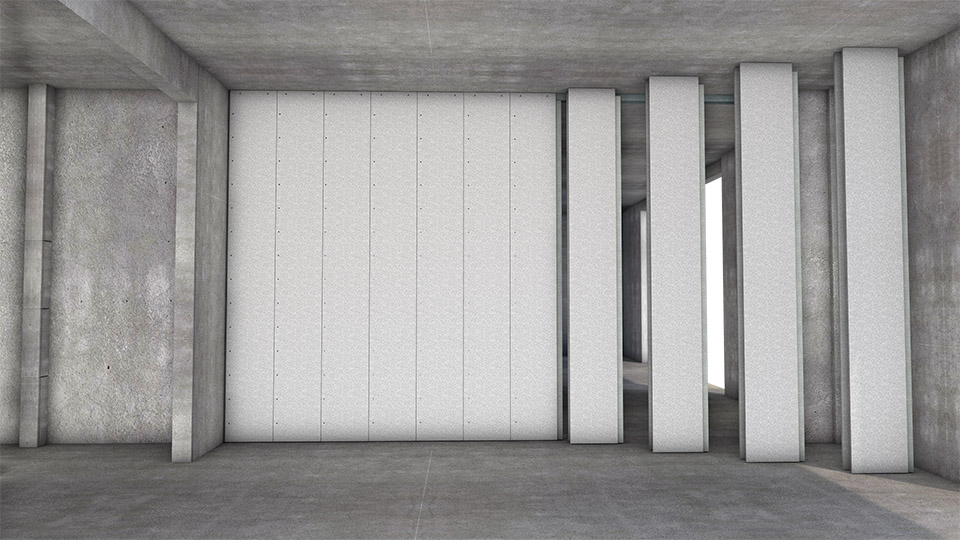

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

Positioning, 90 x 60mm C shape positioning keel fixed to the ceiling and wall; C shape facing sound insulation structure.

Lightweight sound insulation block is fixed with screws and liquid nail.

Decoration is worked out after the installation of sound insulation structure.

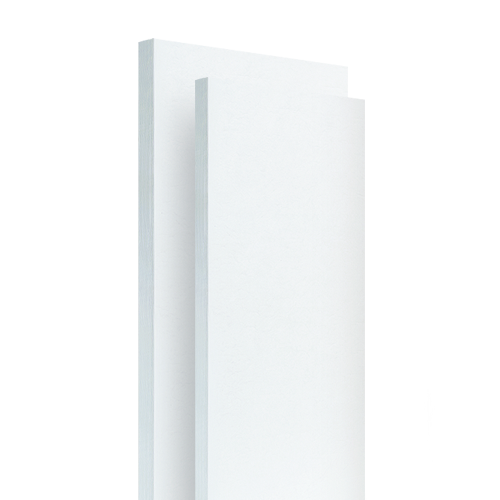

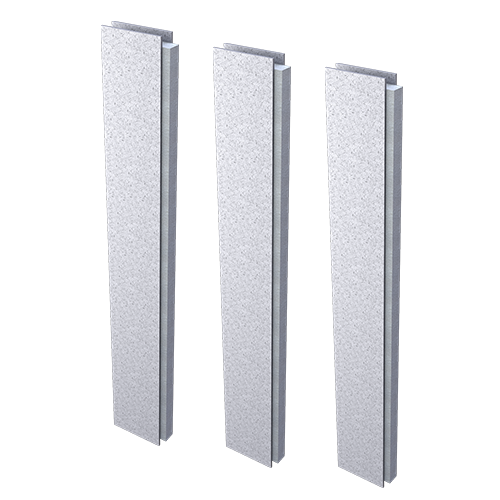

Product name:

“OFF” Lightweight Sound Insulation Block

Model:

G120

Specification:

H3000 x W400 x D110mm

Fireproof:

Grade A

Eco-friendly:

E0

Weight:

68kg/m³

“OFF” Lightweight Sound Insulation Block is your first choice for soundproofing partition, the unique damping composite structure features successfully solved the traditional lightweight partition wall hollowing problem. Excellent sound insulation performance, fireproof, moisture proof, environmental protection, and it is quick and easy installation and construction. Hotel rooms, apartments, and offices preferred.